Dodo Packaging is a leading provider of high-quality custom medicine packaging for businesses in the pharmaceutical industry. Our boxes are designed to meet the unique needs of each business, ensuring that medications are packaged and delivered safely and securely.

We understand that the pharmaceutical industry is highly regulated and that businesses need to comply with strict guidelines. Our team of experts has extensive experience in the packaging industry and can guide you through the process of selecting the right boxes for your specific requirements.

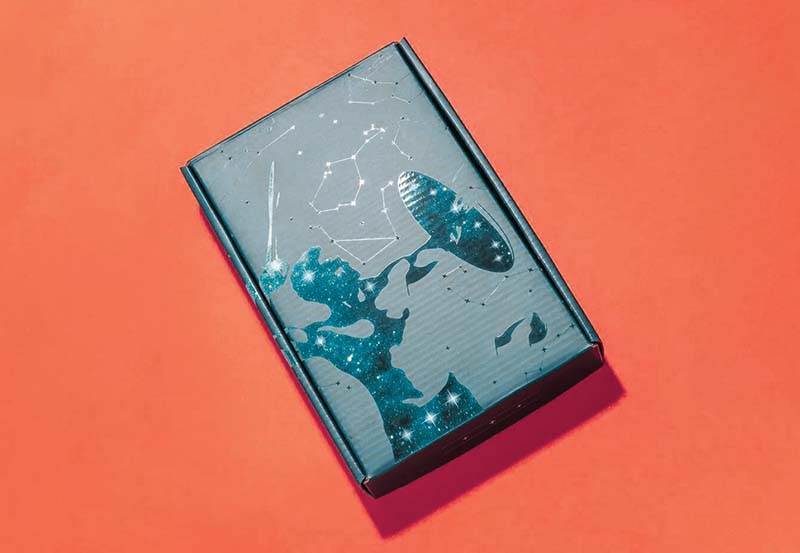

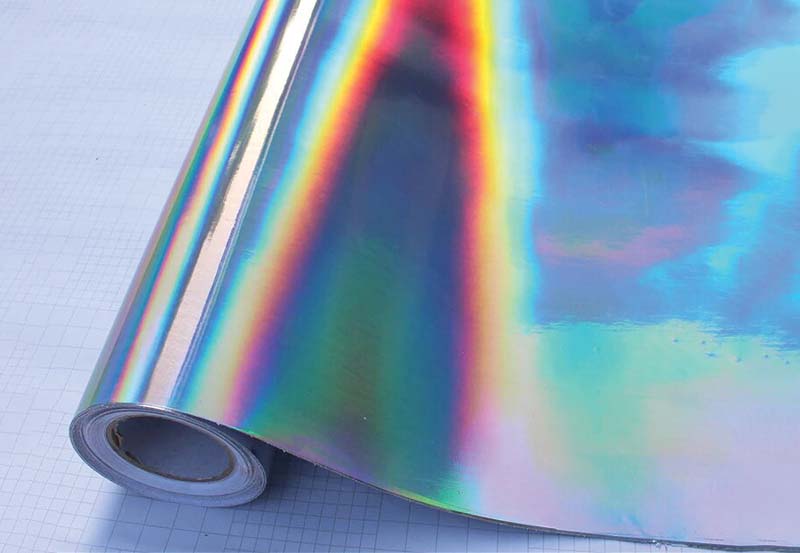

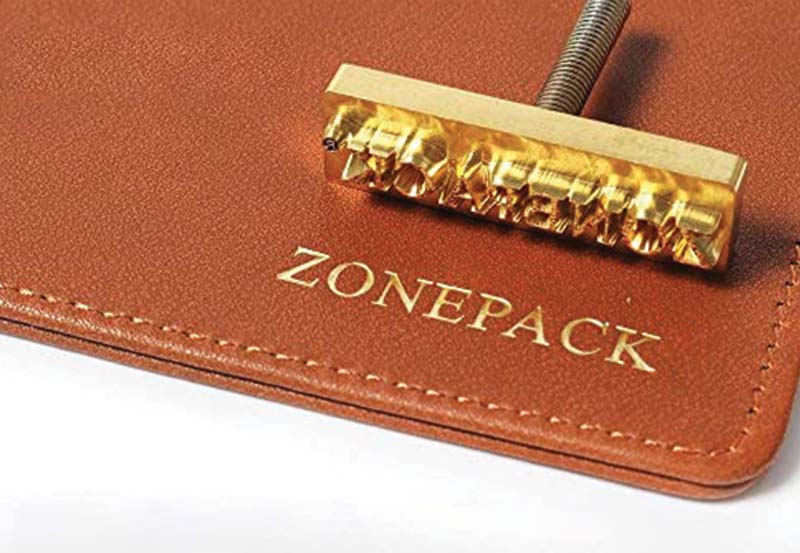

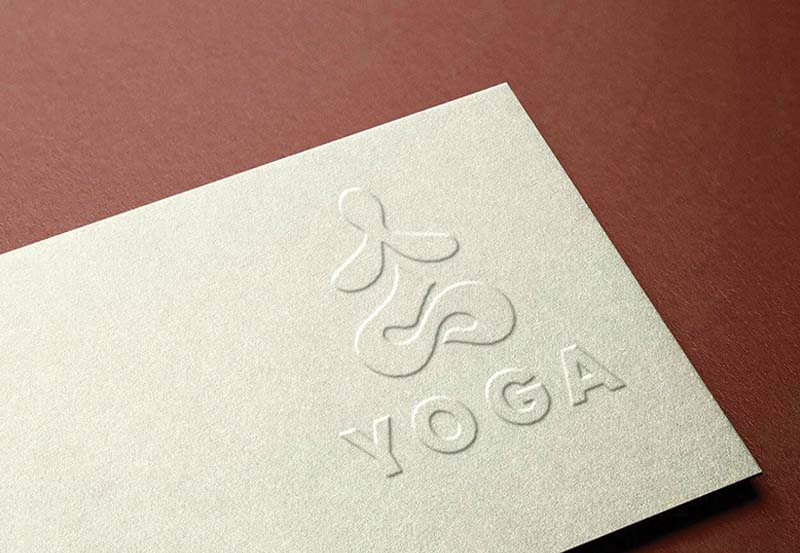

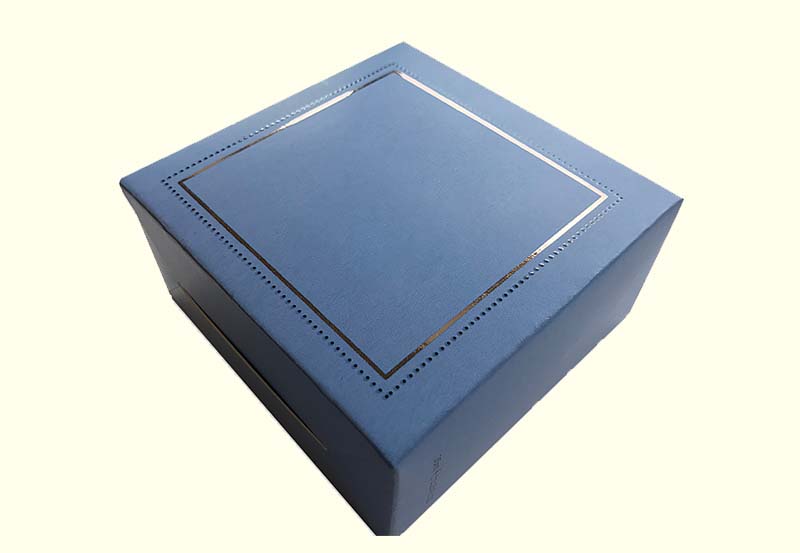

At Dodo Packaging, we use only the highest quality materials to manufacture our boxes, ensuring that they are durable and long-lasting. We offer a wide range of customisation options, including size, shape, colour, and branding, to help you create the perfect boxes for your business.

Our boxes are competitively priced, and we offer flexible ordering options to ensure that businesses of all sizes can take advantage of our services. Contact us today to learn more about how our custom medicine boxes can help your business succeed.