Make a lasting impression on your customers with our custom cereal boxes. We know how important it is to have packaging that protects your product and looks great on shelves. At Dodo Packaging UK, we make durable, visually striking boxes at wholesale prices. We offer coating options like Gloss, Matte, and Spot UV, along with custom sizes and styles. You also get free design help and shipping with a fast turnaround.

Order online

Select Quantity:

Unit Price : £1 for 1000

Available in Stock

STARTING FROM 100 BOXES

8-10BUSINESS DAY TURNAROUND

NO DIE & PLATE CHARGE

HIGH QUALITY OFFSET PRINTING

BEST & COMPETITIVE PRICING

CUSTOM SIZES & STYLE

Premium Cereal Boxes Wholesale - Custom Packaging Solutions UK

Dodo Packaging UK delivers top-quality cereal boxes designed specifically for breakfast product manufacturers and retailers. Our wholesale cereal packaging combines strength with visual appeal. Each box protects your products during transport while attracting customers on store shelves.

We work with brands across the UK to create Custom Food Boxes that drive sales and build recognition. Our cereal boxes come in various sizes from mini portions to family packs. Every design reflects your brand identity while meeting food safety requirements.

Manufacturing excellence drives our approach to cereal box production. Food-grade materials ensure complete safety for consumable products. Multiple quality checks guarantee consistent results across large orders. Our printing technology produces vibrant colors that stay bright throughout the supply chain.

Small businesses and large corporations trust our packaging solutions. We handle orders from 100 pieces to millions of units. Quick turnaround times keep your production schedules on track. Free design consultations help optimize your packaging for maximum impact.

The modern breakfast market demands packaging that works harder than basic containers. Our Catering Packaging extends to restaurants, hotels, and institutional buyers who need bulk solutions. Eco-friendly materials reduce environmental impact while maintaining product protection.

What Are Cereal Boxes Made From

Food packaging requires materials that meet strict safety standards. Our cereal boxes use premium food-grade cardboard sourced from certified sustainable forests. The base material provides crush resistance while staying lightweight for shipping efficiency.

How Do We Ensure Food Safety

Special inner coatings prevent moisture penetration and contamination. This barrier keeps cereals fresh and crispy for months. FDA-approved materials guarantee safe direct food contact. All our processes follow UK and European food packaging regulations.

Quality testing happens at every production stage. Drop tests simulate real shipping conditions. Compression tests ensure boxes survive stacking in warehouses. Color matching systems deliver consistent brand colors across production runs.

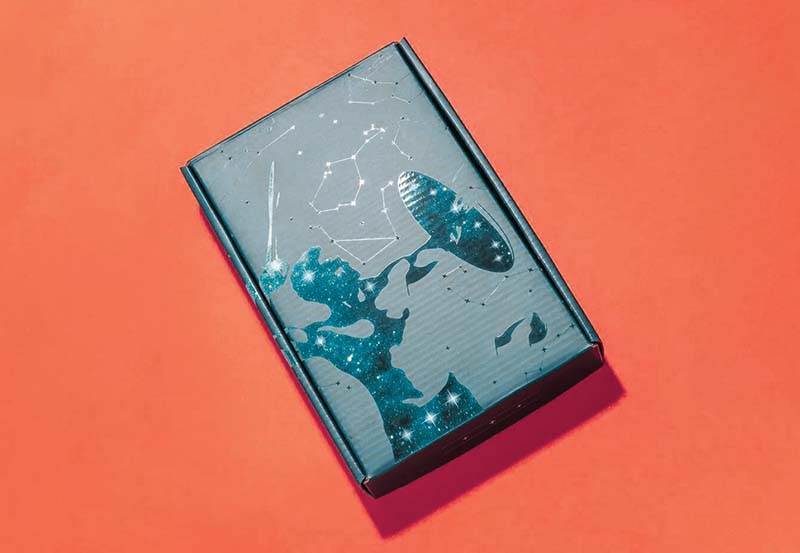

Custom Cereal Boxes Design Options

Your brand deserves packaging that stands out from competitors. We create designs that grab attention and communicate value. Bold graphics work alongside practical features like easy-open tabs and pour spouts.

Size Options for Every Market Need

Different markets require different packaging sizes. Mini cereal boxes work brilliantly for hotels, airlines, and single-serve markets. Standard sizes suit most retail environments. Jumbo packages appeal to families and bulk buyers.

| Box Size | Dimensions | Capacity | Best Used For |

|---|---|---|---|

| Mini | 4" x 2" x 6" | 25-50g | Hotels, airlines, samples |

| Small | 6" x 3" x 8" | 100-200g | Individual portions |

| Standard | 8" x 3" x 10" | 300-500g | Regular retail |

| Large | 10" x 4" x 12" | 750g-1kg | Family size |

| Jumbo | 12" x 5" x 14" | 1.5kg+ | Bulk/wholesale |

Our cereal boxes mini range suits promotional campaigns and travel retail perfectly. Hotels love the convenient single-serving size. Vending machine operators appreciate the compact dimensions. Children's portions work well in school cafeterias.

Custom shapes help brands differentiate themselves from rectangular competitors. Hexagonal designs create unique shelf presence. Cylindrical shapes suggest premium positioning. Die-cut windows let customers see the product inside.

How to Store Cereal Boxes Properly

Proper storage extends product shelf life and maintains box integrity. Temperature and humidity control prevent warping and moisture damage. Stacking methods affect both storage efficiency and product safety.

Best Practices for Cereal Boxes Storage

Warehouse managers need packaging that stacks safely and efficiently. Our reinforced corners prevent crushing under weight. Uniform dimensions maximize pallet loading capacity. Clear labeling speeds inventory management.

- Keep storage areas between 50-70°F temperature range

- Maintain humidity levels below 65% to prevent warping

- Stack boxes no more than 8 high to prevent crushing

- Rotate stock using first-in-first-out principles

- Check for pest activity regularly in storage areas

- Keep boxes away from direct sunlight and heat sources

Retailers appreciate packaging that simplifies shelf management. Our standardized sizing system works with existing store fixtures. Boxes nest together when empty, saving warehouse space. Barcode placement follows industry standards for quick scanning.

What to Do with Empty Cereal Boxes

Environmental responsibility matters to modern consumers and businesses. Empty cereal boxes should enter recycling streams rather than landfills. Proper disposal reduces waste while supporting circular economy principles.

Recycling Guidelines for Empty Boxes

Most UK councils accept cereal boxes in standard recycling collection. Remove any plastic liners before recycling. Flatten boxes to save space in recycling bins. Water-based inks and adhesives break down easily in recycling facilities.

| Material Component | Recyclable | Preparation Required |

|---|---|---|

| Cardboard box | Yes | Flatten and remove liners |

| Plastic liner | Check locally | Separate from cardboard |

| Adhesive | Yes | Water-based breaks down |

| Ink | Yes | Plant-based formulations |

Creative reuse extends the life of empty packaging. Schools use them for art projects and storage. Offices repurpose them for organizing supplies. Home gardeners use them as seed starting containers.

Environmental benefits multiply when businesses choose sustainable packaging. Carbon footprint reduces through local sourcing and production. Waste streams decrease through improved recyclability. Brand reputation improves among environmentally conscious consumers.

Why Choose UK Made Cereal Boxes

Local manufacturing provides significant advantages over imported packaging. Shorter supply chains reduce costs and environmental impact. Faster communication resolves issues quickly. UK quality standards exceed many international alternatives.

Benefits of Working with UK Suppliers

Supporting local businesses strengthens the economy while ensuring reliable supply chains. Our UK facilities respond quickly to urgent orders. No language barriers complicate technical discussions. Time zone alignment simplifies project coordination.

British manufacturing standards prioritize worker safety and environmental protection. Our facilities meet strict emissions requirements. Waste reduction programs minimize environmental impact. Employee welfare programs ensure ethical production practices.

How Much Do Cereal Boxes Cost

Pricing depends on several factors including size, quantity, printing complexity, and material specifications. Volume discounts reward larger orders significantly. Standard sizes cost less than custom dimensions. Simple designs require lower setup costs.

Factors Affecting Cereal Box Pricing

Material costs fluctuate with cardboard market prices. Printing complexity affects setup time and ink usage. Custom die-cutting adds tooling expenses. Rush orders may include expediting fees.

- Quantity - Orders of 10,000+ qualify for bulk pricing

- Size - Standard dimensions cost less than custom sizes

- Printing - Full color costs more than single color

- Materials - Premium stocks add 15-25% to base price

- Timeline - Rush orders include 20-30% surcharge

- Finishing - Special coatings add per-unit costs

Budget planning becomes easier with transparent pricing structures. We provide detailed quotes showing all cost components. No hidden fees surprise customers at delivery time. Volume commitments unlock better pricing tiers.

Cereal Boxes UK Market Trends

British consumers increasingly demand sustainable packaging without sacrificing convenience. Research shows 68% of cereal buyers consider environmental impact when choosing products. Brands respond with recyclable materials and reduced packaging waste.

Current Market Preferences

Health-conscious messaging influences packaging design significantly. Organic and natural positioning requires earth-tone colors and minimal graphics. Protein-rich cereals target fitness enthusiasts with bold, energetic designs. Children's cereals still rely on cartoon characters and bright colors.

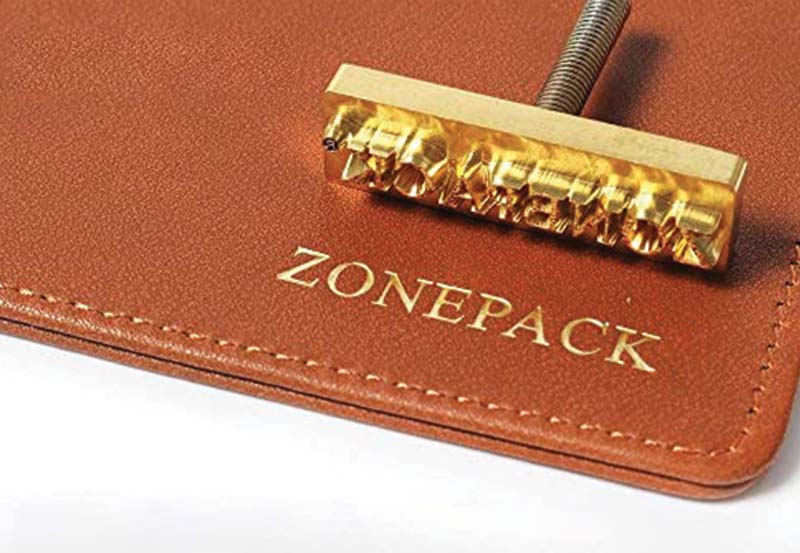

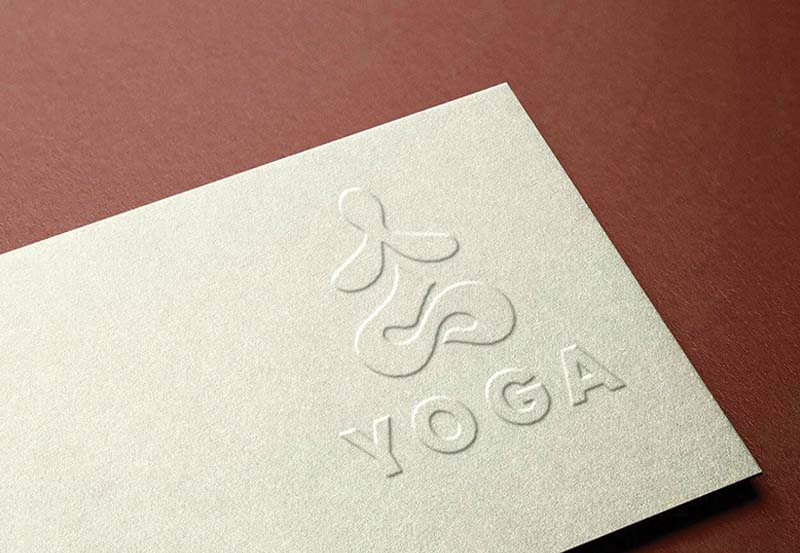

Premium positioning through packaging helps justify higher prices. Matte finishes suggest sophistication and quality. Embossed logos create tactile brand experiences. Spot UV highlights key product benefits effectively.

Online retail growth changes packaging requirements dramatically. Shipping boxes need extra protection during delivery. E-commerce designs must photograph well for website listings. Unboxing experiences influence customer satisfaction and reviews.

Custom Printing and Finishing Options

Our printing capabilities handle everything from simple text to complex photographic images. Digital printing suits short runs and testing. Offset printing delivers consistency across large volumes. Flexographic printing works well for simple designs.

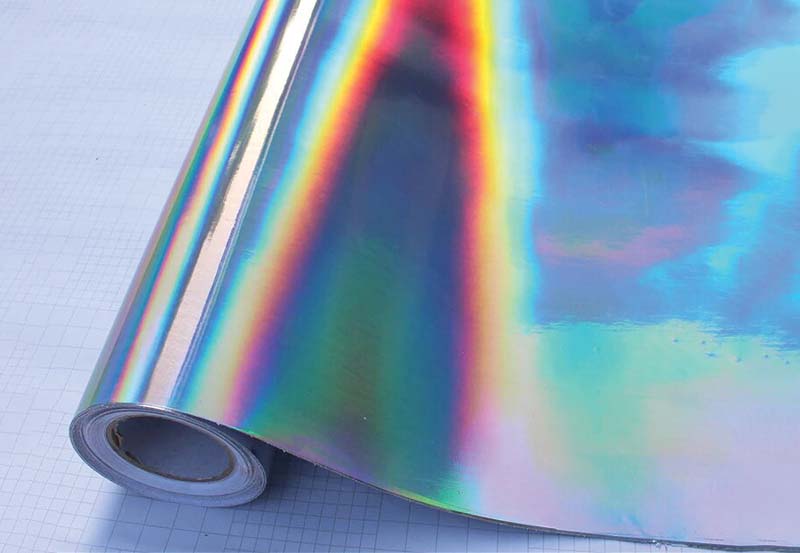

Available Coating and Enhancement Options

Surface treatments protect printing while adding visual appeal. Gloss coatings maximize color vibrancy and provide scuff resistance. Matte finishes create sophisticated appearances that appeal to premium brands. Spot UV selectively highlights important design elements.

Gloss Coating Benefits

- Maximum color brightness and contrast

- Excellent scuff and scratch resistance

- Professional appearance that suggests quality

- Works well with photographic images

- Easy to clean and maintain appearance

Matte Coating Advantages

- Sophisticated, understated appearance

- Reduces fingerprint visibility significantly

- Complements natural and organic positioning

- Creates tactile contrast with gloss elements

- Appeals to environmentally conscious consumers

Spot UV Applications

- Highlights logos and brand names effectively

- Creates textural interest without additional colors

- Combines matte and gloss in single design

- Draws attention to key product benefits

- Adds perceived value at reasonable cost

Enhancement options include embossing and debossing for dimensional effects. Foil stamping adds metallic accents that suggest premium positioning. Die-cut windows let customers see products while maintaining structural integrity.

Quality Control and Testing Procedures

Every batch undergoes rigorous testing before shipment approval. Visual inspections catch printing defects early. Structural tests ensure boxes survive shipping and handling. Color matching verifies brand consistency across production runs.

Our Testing Process

Manufacturing quality starts with incoming material inspection. Cardboard thickness and moisture content must meet specifications. Printing inks undergo color accuracy testing. Adhesives require strength and food safety verification.

- Material Inspection - Check thickness, moisture, and surface quality

- Print Quality Review - Verify colors, registration, and clarity

- Structural Testing - Confirm crush strength and closure integrity

- Food Safety Compliance - Test for contamination and chemical migration

- Final Inspection - Random sampling before packaging for shipment

- Customer Feedback - Monitor satisfaction and address issues promptly

International certifications validate our quality management systems. ISO 9001 ensures consistent processes and continuous improvement. BRC certification confirms food safety compliance. FSC certification guarantees sustainable material sourcing.

How Long Does Production Take

Standard cereal boxes typically ship within 10-12 working days from approved artwork. Custom sizes and special finishes may require additional time. Rush orders can be accommodated with expedited scheduling when capacity allows.

Production Timeline Breakdown

Artwork review and technical analysis takes 1-2 business days. Digital proofing adds another 1-2 days for approval. Pre-production sampling requires 2-3 days for complex designs. Full production runs consume 5-7 days depending on quantity and complexity.

Week 1

- Day 1-2: Artwork review and technical feasibility check

- Day 3-4: Digital proof creation and client approval

- Day 5: Pre-production sample manufacturing if required

Week 2

- Day 1-5: Full production run with quality monitoring

- Day 6-7: Final inspection, packaging, and dispatch preparation

Peak seasons may extend timelines due to increased demand. Christmas and back-to-school periods create capacity constraints. Early ordering helps secure preferred delivery dates. Flexible scheduling accommodates urgent requirements when possible.

Why Dodo Packaging Leads the Market

Our combination of quality, service, and value sets us apart from competitors. UK-based manufacturing ensures faster response times and better communication. Direct manufacturer pricing eliminates middleman markups. Experienced staff understand industry requirements and regulations.

What Makes Us Different

Customer service excellence drives everything we do. Dedicated account managers provide personalized attention throughout projects. Technical support helps optimize designs for production efficiency. Quality assurance prevents problems before they affect your business.

Continuous investment in equipment and training keeps us ahead of industry developments. New printing technologies improve quality while reducing costs. Staff training ensures that staff members are up to date on current regulations and best practices. Research and development create innovative solutions for emerging market needs.

Get Your Custom Cereal Boxes Quote Today

Contact Dodo Packaging UK today for competitive wholesale pricing on premium cereal boxes. We offer free design consultations, fast turnaround times, and exceptional quality control. Choose from gloss, matte, or spot UV coating options. Custom sizes and styles available with free shipping throughout the UK. Our high-quality materials and professional printing options will make your products stand out on any shelf.

Call now or request your free quote online to discover how we can boost your brand's shelf presence and sales performance.

| Specification | Details | Material Options | Finishing Choices | Add-ons & Features | Usage/Application |

|---|---|---|---|---|---|

| Dimensions | All custom sizes available including mini, family, and bulk packs | White SBS, Brown Kraft, Corrugated E-Flute, Recycled Board | Gloss, Matte, Spot UV | Easy-open flaps, resealable tops, window cut-outs | Retail shelves, Wholesale supply, Storage use |

| Printing | Full CMYK and PMS spot colours, or blank cereal boxes empty | 10pt to 28pt thickness (60lb–400lb) | Offset & Digital printing | Logo printing, QR codes, Nutrition panels, Promo messages | Supermarkets, Schools, Hotels, Catering |

| Paper Stock | Food-grade, eco-certified and recyclable board | C1S/C2S SBS, Kraft board, Recycled paper | Lamination, Soft Touch, Anti-scratch | Grease-resistant lining, FDA-compliant coatings | Breakfast cereals, Health foods, Organic products |

| Quantities | From 100 units up to 500,000+ | Wholesale pricing available | Low MOQs supported | Subscription & auto-restock options | Local brands, Startups, Large cereal manufacturers |

| Coating | Food-safe and moisture-resistant options | Custom coating support | Gloss, Matte, Spot UV, Anti-fingerprint | Inside & outside coating available | Long shelf-life, Freshness retention, Branding |

| Default Process | Die-cutting, Scoring, Gluing, Perforating | Custom dieline creation on request | Smooth fold edges, Durable flaps | Ships flat or pre-assembled | Retail packaging, Export-ready cartons |

| Options | Mini boxes, Family-size boxes, Storage-style packs | Flat-pack or ready-to-use delivery | Print inside & outside available | Tear locks, Inserts, Folded edges | Kids packs, Variety packs, Promotional offers |

| Proof | Digital PDF proof, 3D rendering, or sample on request | Upload files in AI, EPS, PDF formats | Pre-press checks included | Mockup approval before final print | First-run production, Sampling, Bulk orders |

| Turnaround Time | Standard: 7–10 business days; Rush: 4–6 days | Rush service on request | Expedited printing & shipping | Real-time order tracking | Seasonal campaigns, Launch events, Retail supply |

| Shipping | Free delivery across the UK | Flat-packed for cost savings | Worldwide & urgent shipping available | White-label delivery, Bulk pallet shipping | UK retailers, Export orders, Franchise supply |

| Design Support | Free dieline templates & reviews | Custom layout files provided | Colour & alignment guidance | 1-on-1 design consultation | Food startups, Packaging teams, Branding agencies |